- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Customize Unique LED Lens, LED Optics Component For Outdoor Lighting And Indoor Lighting

| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

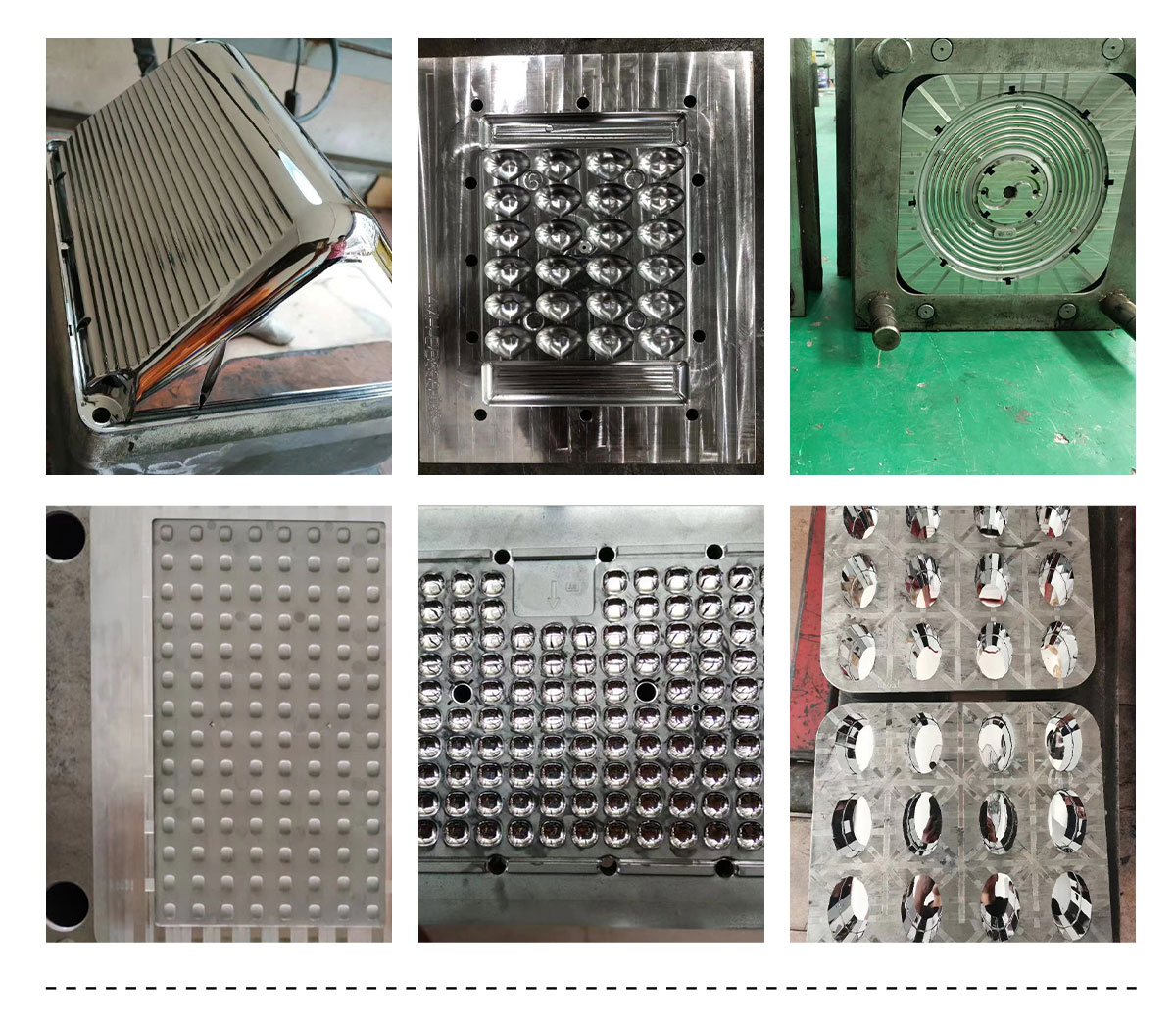

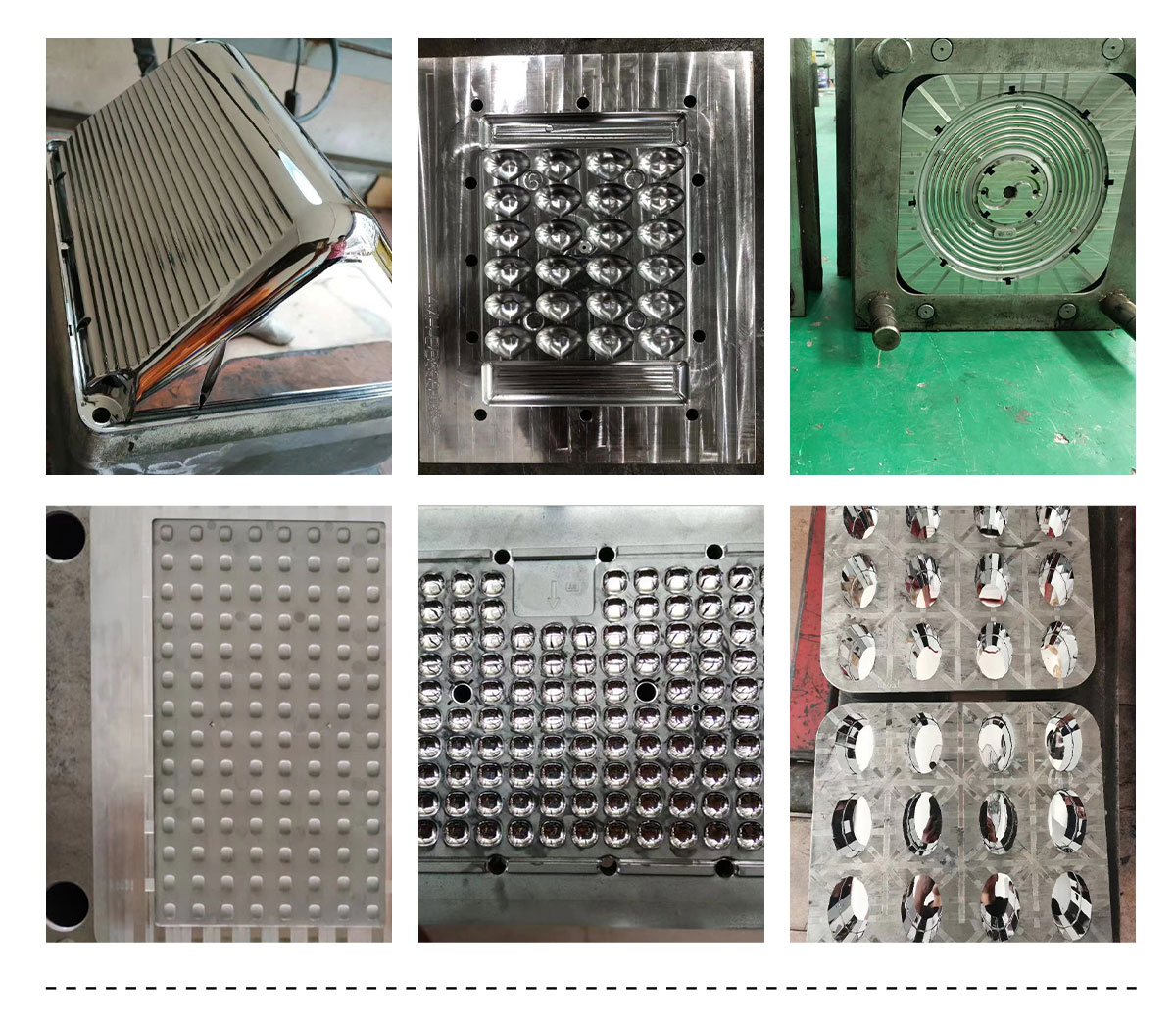

Product name: LED lens mold Mould cavity: Customized Height: Customized Dimention: Customized Type: Plastics injcetion molding Injection machine specification: Depends on part size Gate and runner: Cold runner or hot runner Material: S136 steel |  |

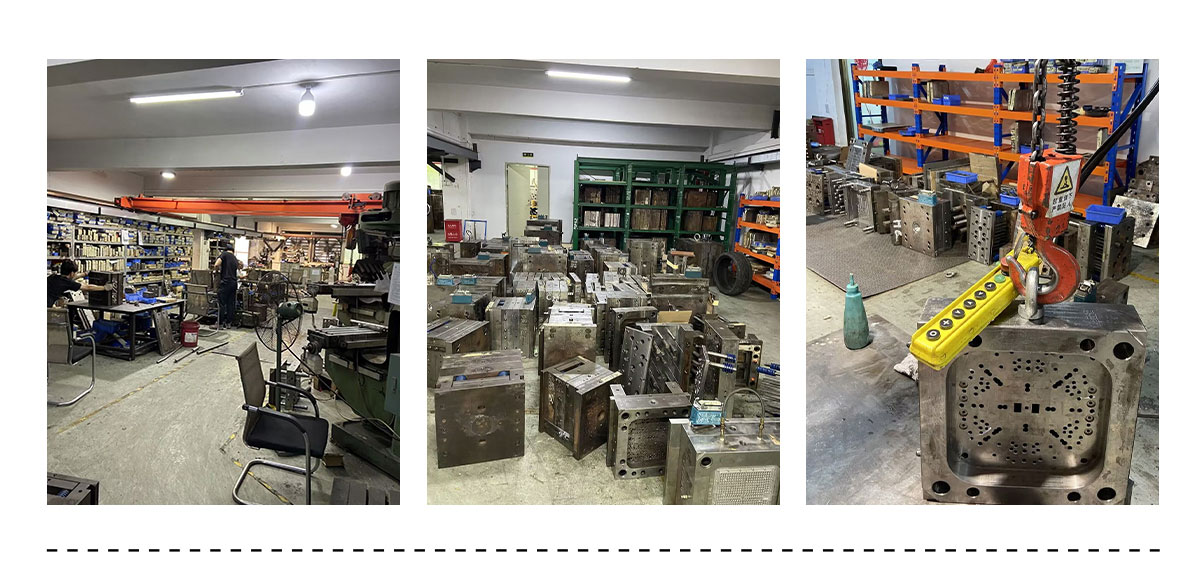

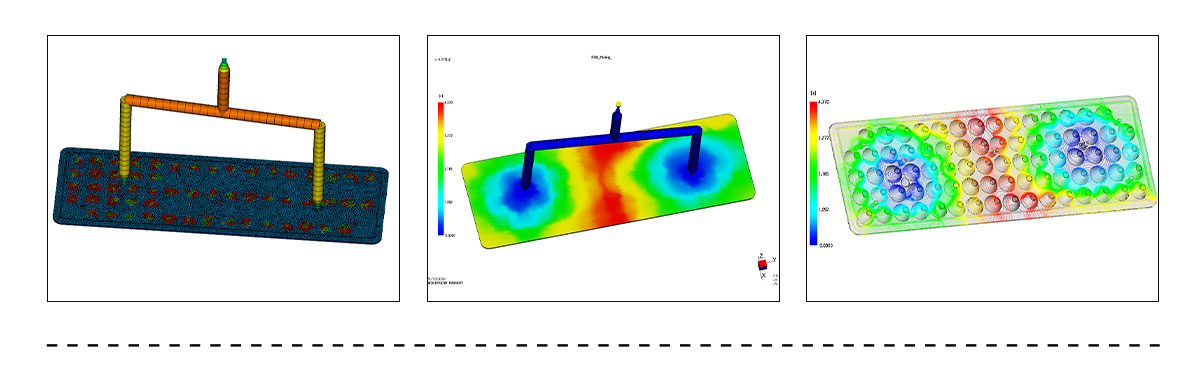

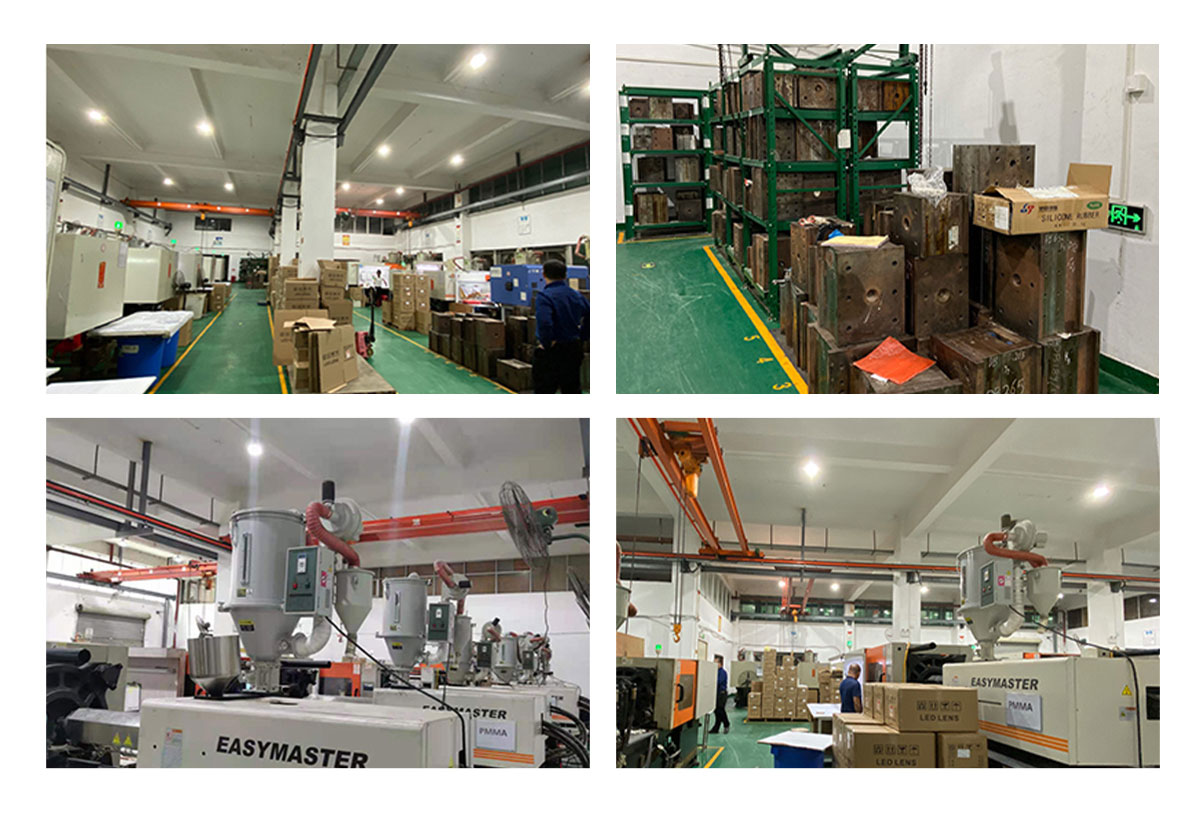

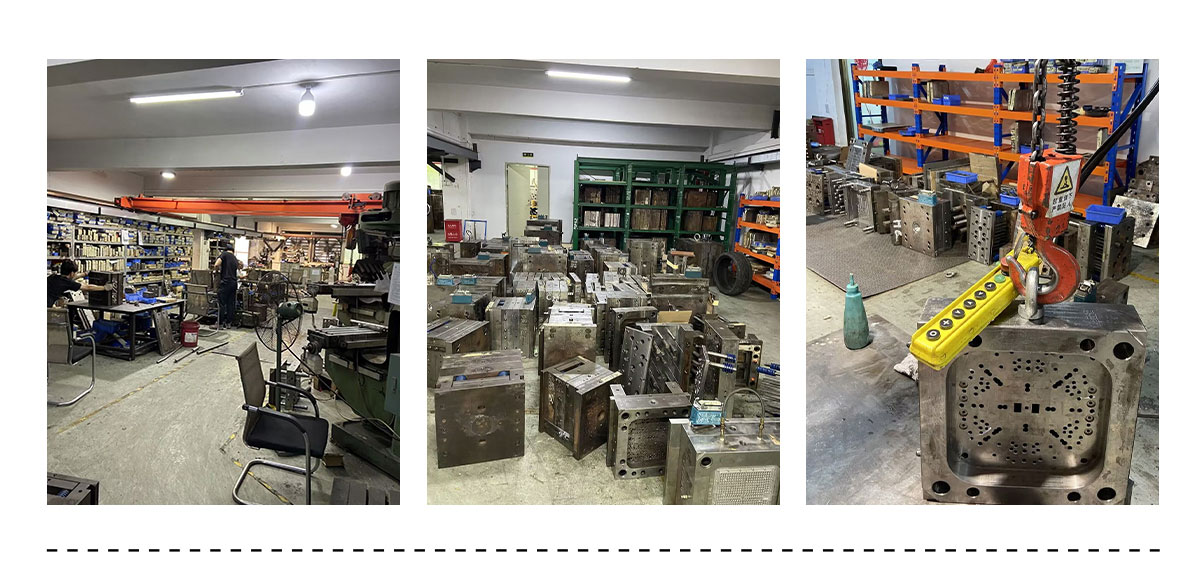

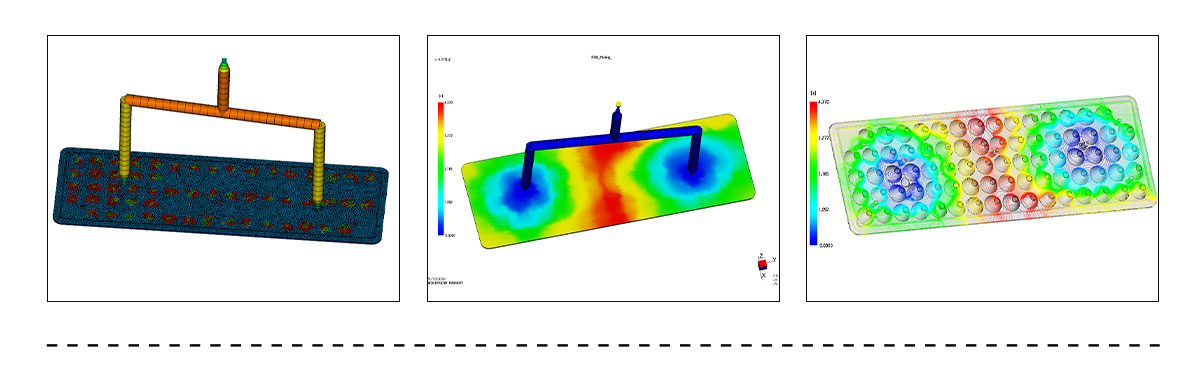

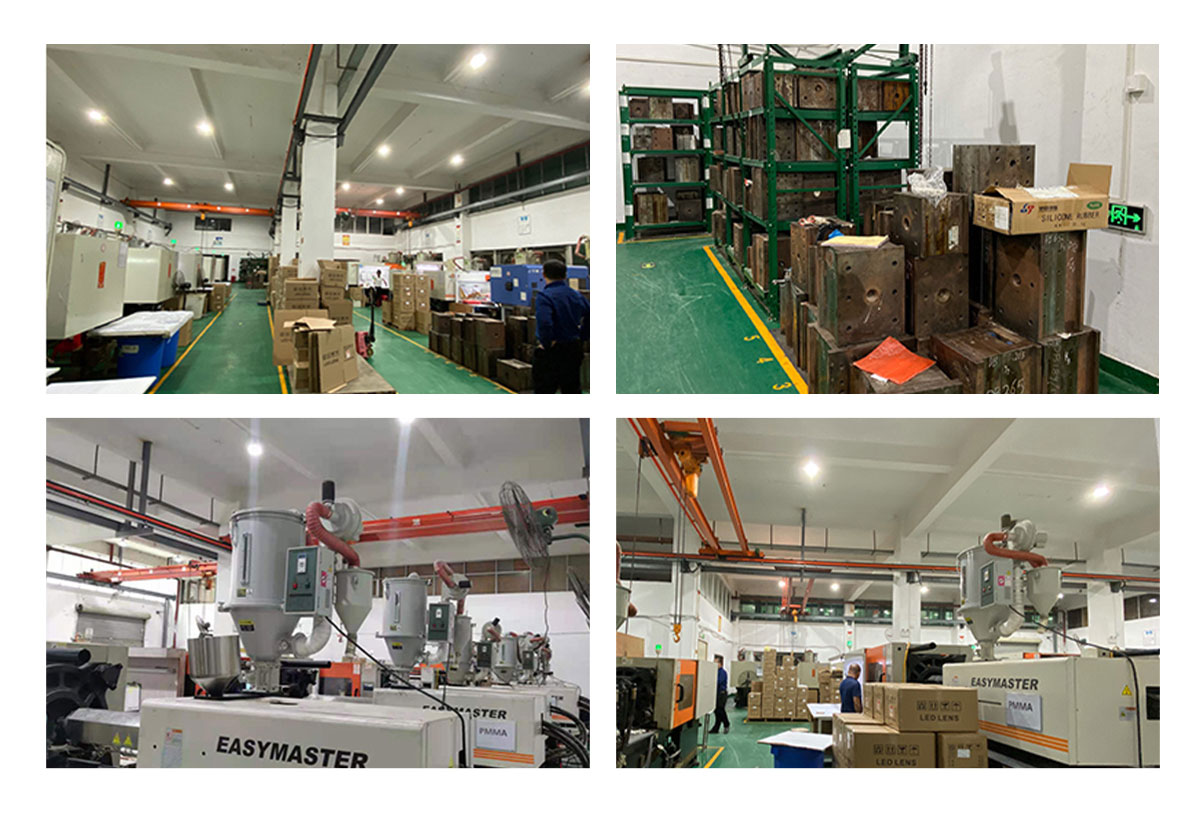

We understand the importance of precision and reliability in Custom Plastic Injection Mould manufacturing process. Brightlx will offer design 3D work on Solickwords or PRO/Engineer AUTO-CAD, and do the design for manufacture(DFM) and mold analysis to solve the issues that may happen in production, it will much avoid the predicted issue and make the injection produce smoothly.

The LED lens is a high-precision optical accessory, which has extremely high requirements on the accuracy of the mold. Because the tolerances are not matched, the design optics of the lens will be affected, so the production of the mold must be controlled very accurately, we provides processing of such high-precision molds: ultra-precision processing machines, WEDM, EDM, CNC comprehensive processing machines, screen grinders, milling machines, CNC electrical discharge machines, surface contouring instruments, etc. The most accurate part of the mold is the optical part, so we only select the best grade of steel, and then use the ultra-precision processing machine to process the curved surface with aspheric technology.

Hot tags: LED lens mold, led optics mold, plastics injection mold, mold tooling, cnc LED lens mold, polishing LED lens mold, wedm LED lens mold, edm LED lens mold, custom plastic injection mould, China, Customized, custom, OEM, manufacturing company, manufacturers, suppliers, factory

Product name: LED lens mold Mould cavity: Customized Height: Customized Dimention: Customized Type: Plastics injcetion molding Injection machine specification: Depends on part size Gate and runner: Cold runner or hot runner Material: S136 steel |  |

We understand the importance of precision and reliability in Custom Plastic Injection Mould manufacturing process. Brightlx will offer design 3D work on Solickwords or PRO/Engineer AUTO-CAD, and do the design for manufacture(DFM) and mold analysis to solve the issues that may happen in production, it will much avoid the predicted issue and make the injection produce smoothly.

The LED lens is a high-precision optical accessory, which has extremely high requirements on the accuracy of the mold. Because the tolerances are not matched, the design optics of the lens will be affected, so the production of the mold must be controlled very accurately, we provides processing of such high-precision molds: ultra-precision processing machines, WEDM, EDM, CNC comprehensive processing machines, screen grinders, milling machines, CNC electrical discharge machines, surface contouring instruments, etc. The most accurate part of the mold is the optical part, so we only select the best grade of steel, and then use the ultra-precision processing machine to process the curved surface with aspheric technology.

Hot tags: LED lens mold, led optics mold, plastics injection mold, mold tooling, cnc LED lens mold, polishing LED lens mold, wedm LED lens mold, edm LED lens mold, custom plastic injection mould, China, Customized, custom, OEM, manufacturing company, manufacturers, suppliers, factory