- 1. Custom Design ServicesBrightlx provides fully tailored lens design services covering various industries, including industrial lighting, commercial lighting, architectural lighting, automotive lighting, stage lighting, aircraft lighting, medical lighting, and specifically tailored for LED street light lenses. Whether it's improving the light efficiency of existing fixtures or developing new projects, our design team can provide complete optical solutions from concept to product. We are also capable of meeting complex optical structures and special material requirements for LED street light lens OEM manufacturing.

- 2. Optical Design SupportTo help clients reduce R&D costs, we offer free optical design services. Our optical experts can optimize lens performance based on the specific requirements of the application scenario to ensure the final LED street light lens product achieves the best results.

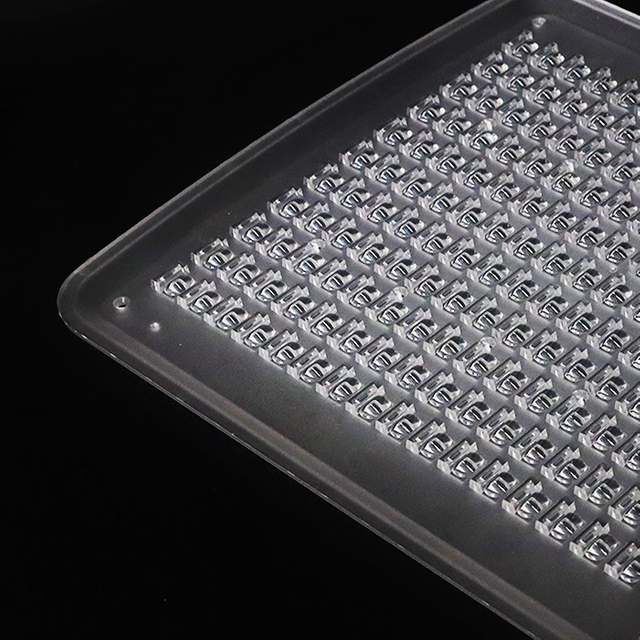

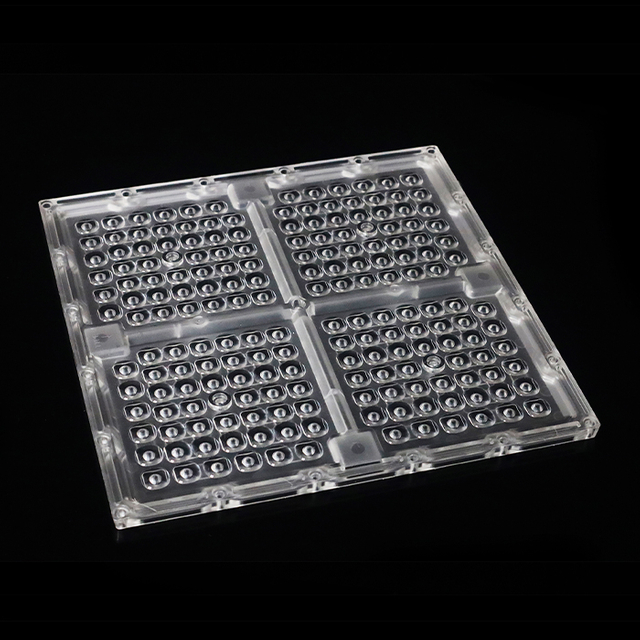

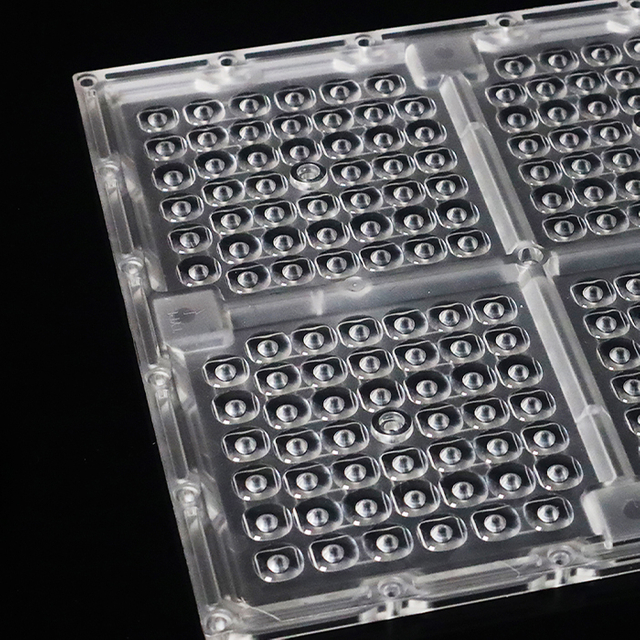

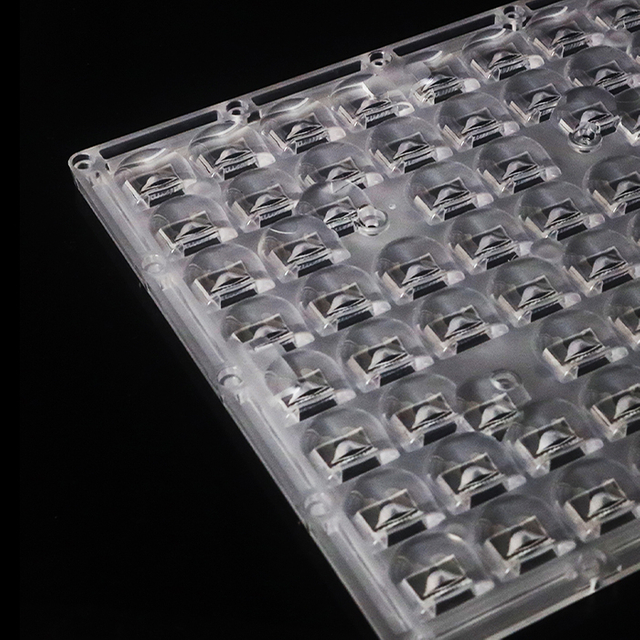

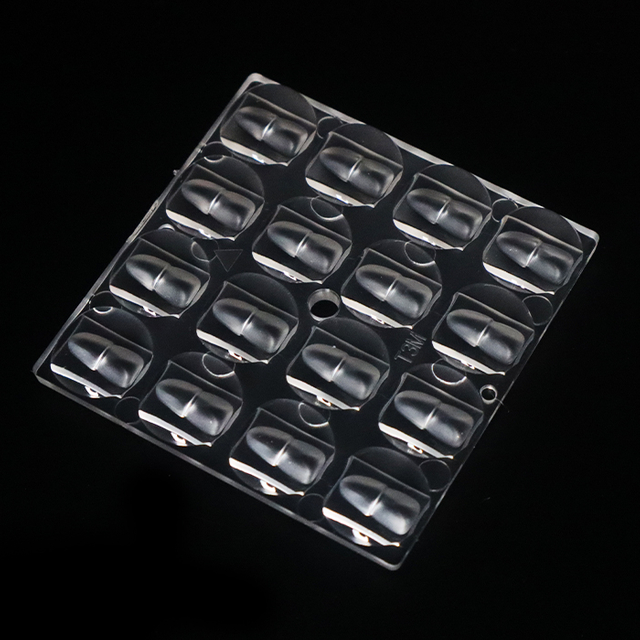

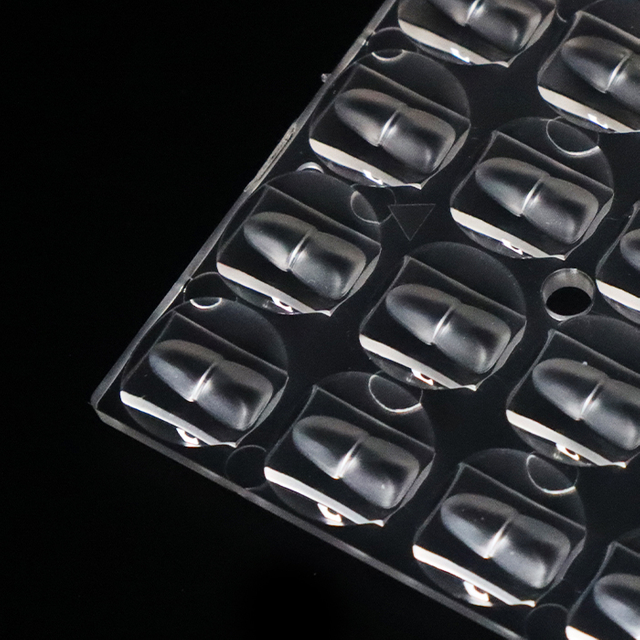

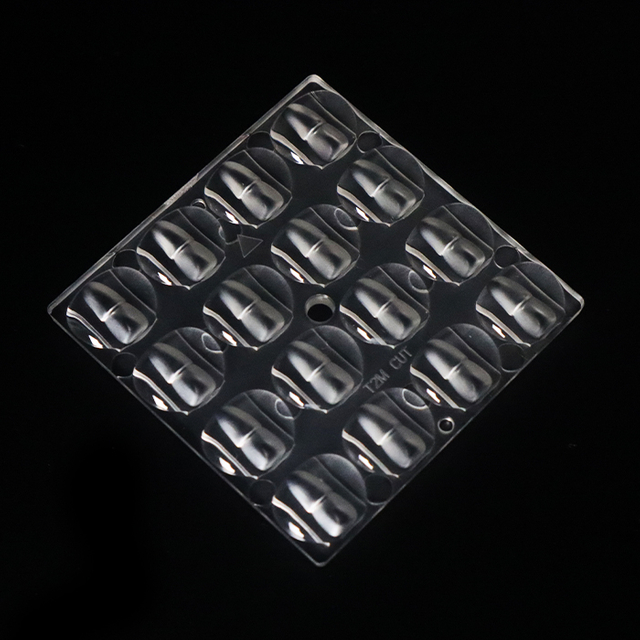

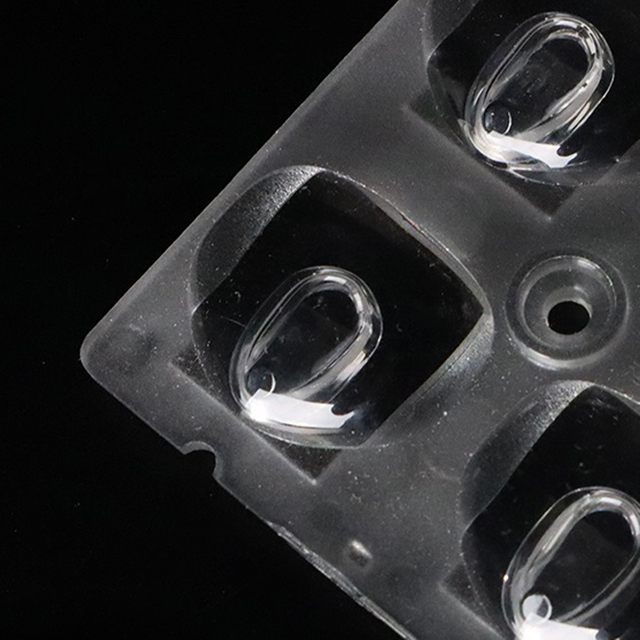

- 3. Mold Manufacturing and Injection MoldingBrightlx has a complete mold-making facility and various injection molding machines with different tonnages, allowing us to design and manufacture lens molds in-house. This enables us to quickly respond to customer customization needs and provide cost-effective lens manufacturing services specifically for LED street light lenses.

- 4. High-Precision Optical SolutionsOur lenses are widely used in various applications, including residential lighting, automotive lighting, stage entertainment lighting, emergency rescue lighting, medical lighting, and notably, LED street lighting. We excel in producing high-precision secondary optical products to ensure optimal light control in fixtures, especially for LED street light lenses.

- 5. Material Selection and Application RecommendationsBased on customer usage characteristics or requirements, we recommend the most suitable materials for LED street light lenses. The materials we commonly use include PMMA-VH001 and PC-1250Z, both of which perform exceptionally well in indoor and outdoor industrial lighting fixtures, street lighting, perimeter lighting, and architectural lighting, offering a high cost-performance ratio.The advantage of Brightlx LTD lies in our ability to quickly respond to customer needs and provide professional technical support as a trusted LED street light lens OEM manufacturer. From design to finished product, we ensure that every step meets the highest quality standards. By closely collaborating with our clients, our goal is to help them achieve more efficient and environmentally friendly lighting solutions tailored for LED street light lenses.