Why Choose Us

With nearly 20 years of experience in optical design specializing in LED high bay lens manufacturing, Brightlx LTD stands as a leading LED high bay lens manufacturer with deep technical accumulation in the field of LED lenses. As an esteemed LED high bay lens manufacturer, we possess a strong engineering team and comprehensive production capabilities, allowing us to provide customers with efficient and precise optical solutions. Our core advantages include:

Deep industry experience

Brightlx has accumulated many years of experience in the field of optics, particularly in the automotive and industrial fields with high precision requirements. As a seasoned LED high bay lens manufacturer, our nearly 20 years of experience in optical design equips us to provide customers with professional advice and customized solutions tailored for LED high bay lenses.

Mature technical team

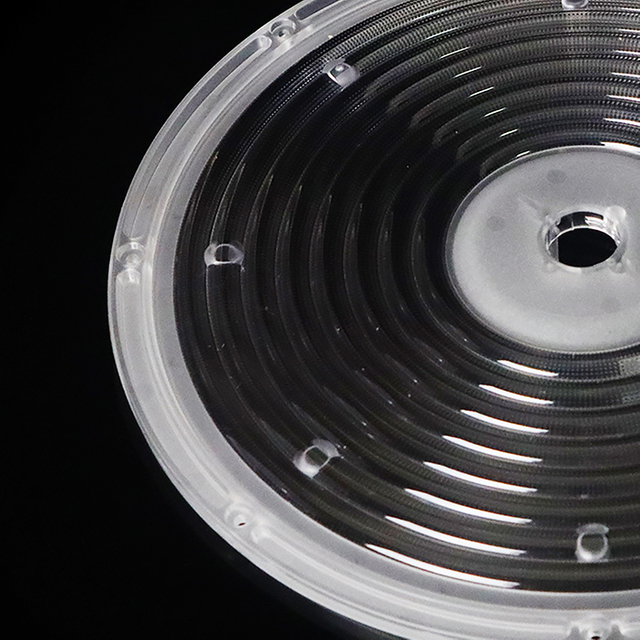

We have a technically mature, passionate, and creative engineering team that stays abreast of the latest trends, continuously optimizes and innovates, and provides customers with the most advanced optical design and products. As an industry-leading LED high bay lens manufacturer, our team ensures that our offerings remain at the forefront of technological advancements.

Precise customized service

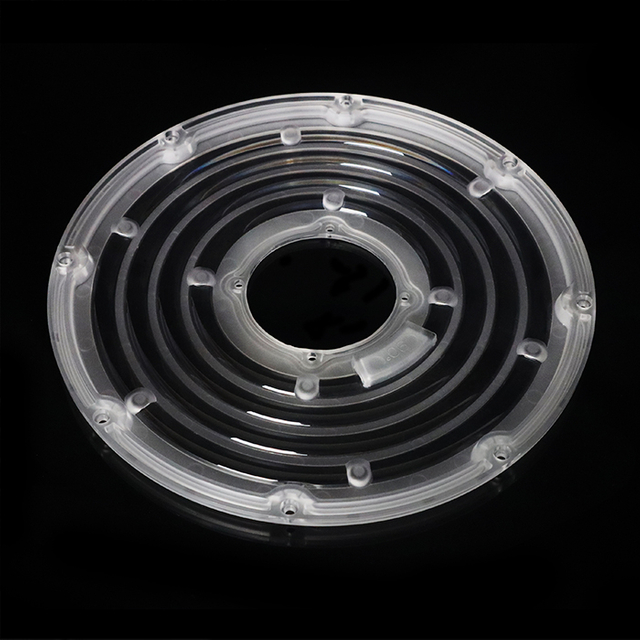

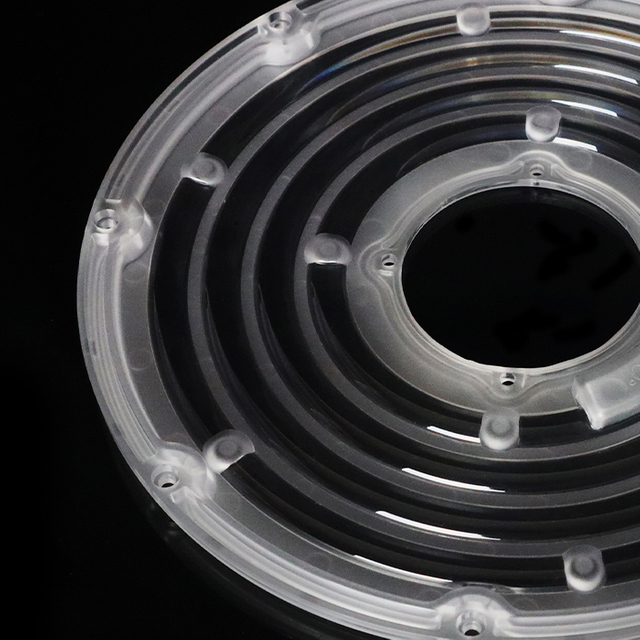

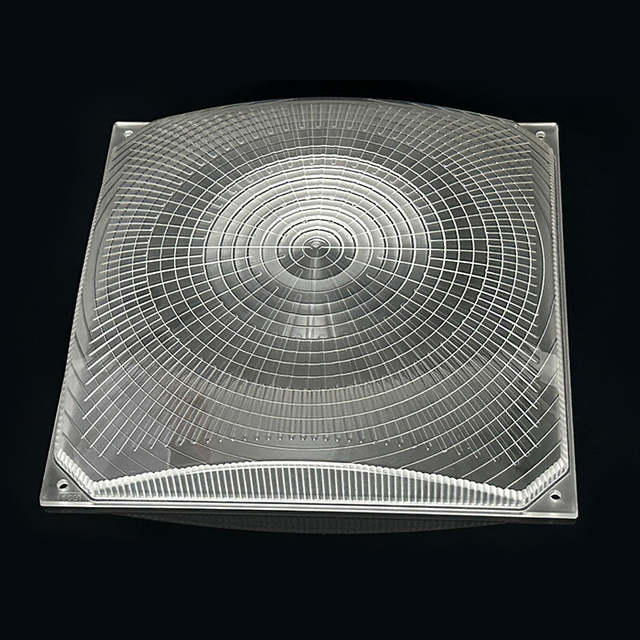

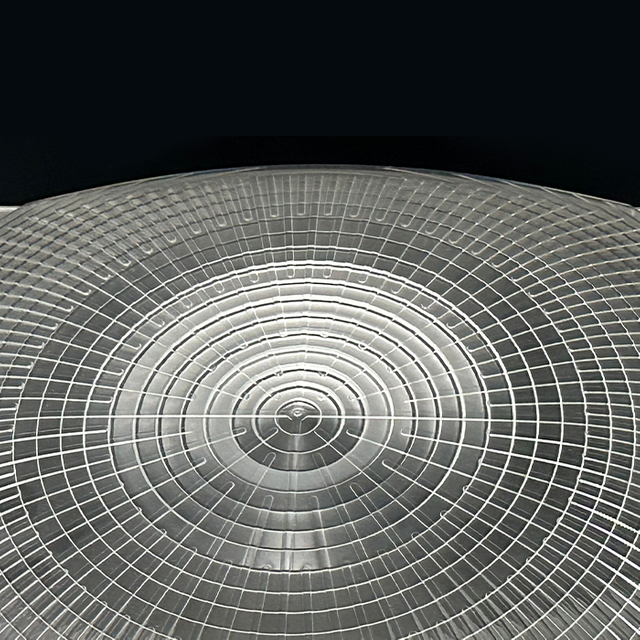

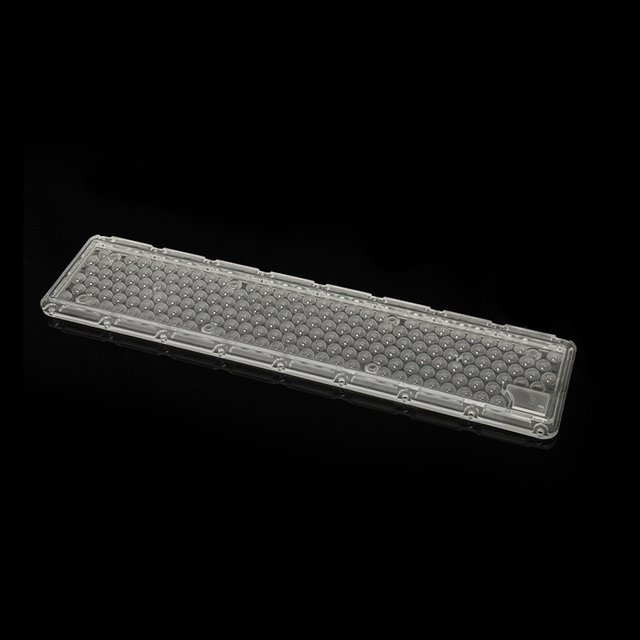

Brightlx produces fully customized LED lenses according to customer drawings and technical requirements, which are widely used in various lighting applications including industrial lighting, commercial lighting, architectural lighting, motor vehicle lighting, stage lighting, aircraft lighting, medical lighting, and specifically, LED high bay lighting. Whether it's a complex optical structure or special material requirements, we can accurately meet them as a proficient LED high bay lens manufacturer.

Cost-effectiveness

By optimizing production processes and mold manufacturing technology, Brightlx, as a reliable LED high bay lens manufacturer, is able to effectively control production costs and provide customers with competitive prices. We understand the competitive pressures faced by our customers in the market, so we are committed to offering cost-effective product solutions tailored for LED high bay lenses.

Advanced production equipment

Our production facilities are equipped with injection molding machines ranging from 80 tons to 480 tons, capable of coping with various production needs. As a trusted LED high bay lens manufacturer, Brightlx has successfully served more than 3,000 projects and has grown and developed alongside our customers, leveraging our state-of-the-art equipment.

Strict quality control

Brightlx implements strict quality control on every link of production. Every step from raw materials to finished product shipment is rigorously tested and audited to ensure that the optical performance and quality of each LED high bay lens product meet industry standards. As a dedicated LED high bay lens manufacturer, we prioritize quality and consistency in our offerings.

With these advantages, Brightlx LTD has established itself as a trusted LED lens solution supplier for global customers, providing comprehensive technical support and production services for a wide range of lighting applications, particularly specializing in LED high bay lens manufacturing.