Why Choose Us

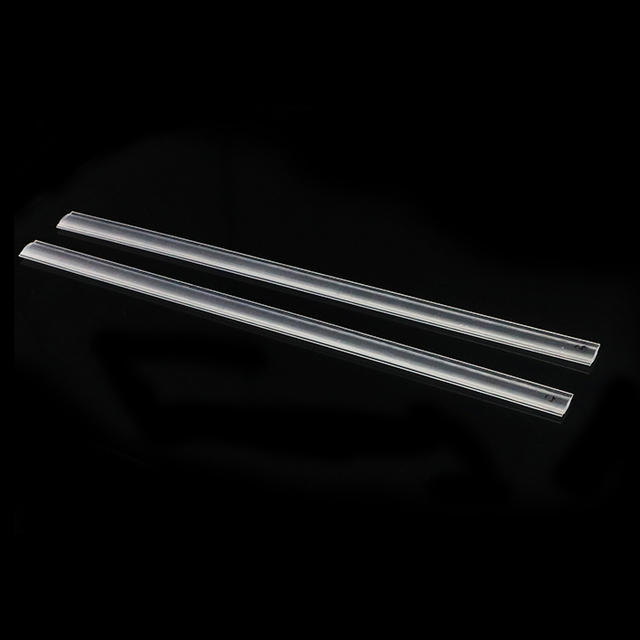

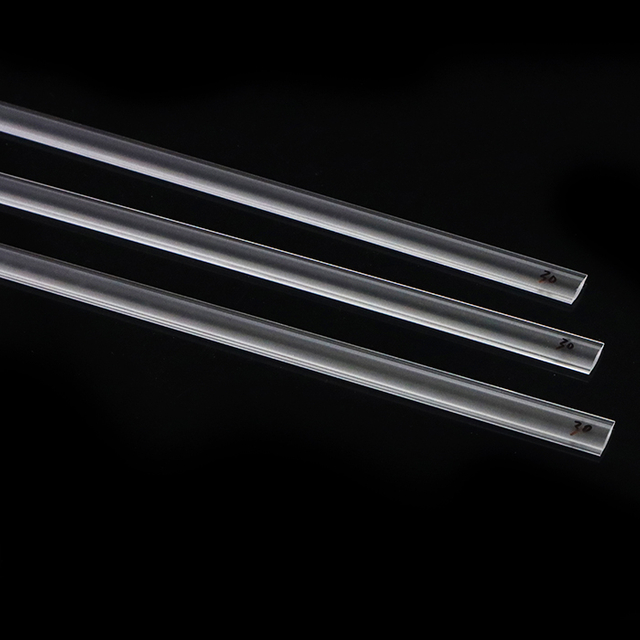

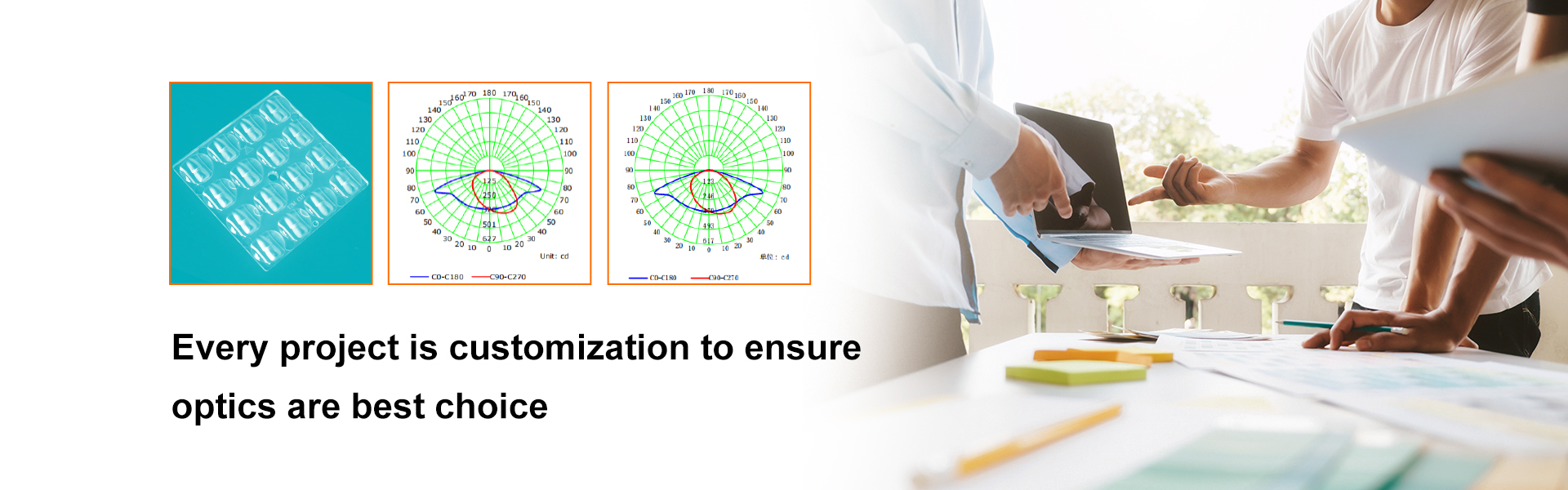

Customization Expertise: As a leading LED linear lens supplier, we excel in designing and producing custom LED linear lenses tailored to your exact specifications, ensuring the perfect fit for your unique projects. Our team of experts leverages their deep industry knowledge and experience to create lenses that meet your precise needs, setting us apart as a trusted LED linear lens supplier.

Advanced Technology: We utilize cutting-edge technology, including injection molding, extrusion, and CNC machining, to deliver high-precision lenses for both prototypes and mass production. Our advanced manufacturing processes ensure that every lens we produce, as a dedicated LED linear lens supplier, meets the highest standards of accuracy and quality.

Strict Quality Control: Quality is paramount at our LED linear lens supplier company. Our rigorous quality assurance protocols ensure that every lens we produce meets top standards for optical clarity and durability. We conduct thorough testing and inspections at every stage of production to guarantee that our lenses exceed your expectations.

Flexible MOQs: Understanding the needs of our clients, we offer low minimum order quantities (MOQs) as an accommodating LED linear lens supplier. This makes it easy for you to start small and scale up as your project grows, offering flexibility and convenience without compromising on quality.

End-to-End Service: From initial design consultation to production, packaging, and delivery, we manage the entire process as your comprehensive LED linear lens supplier. Our streamlined operations ensure fast lead times and cost-effective solutions, allowing you to focus on other aspects of your project.

Client Focused: We prioritize your needs, offering technical support and tailored solutions to meet your unique requirements. Our client-centric approach builds strong, long-term partnerships, fostering trust and reliability as your preferred LED linear lens supplier.

Competitive Price: Our efficient production processes and economies of scale allow us to offer cost-effective yet high-quality solutions, delivering great value for your investment. As an experienced LED linear lens supplier, we understand the importance of balancing cost and quality, ensuring that you receive the best possible return on your investment.

Choose us, the trusted LED linear lens supplier, for reliable, custom LED linear lenses that elevate your lighting projects to new heights. Our expertise, advanced technology, strict quality control, flexible MOQs, end-to-end service, client-focused approach, and competitive pricing make us the ideal partner for your lighting needs.