- OEM/ODM ServicesAs an experienced Led Lens custom manufacturer, we provide comprehensive OEM and ODM services, delivering bespoke LED lenses tailored to meet the specific requirements of our clients. Whether it involves crafting a unique lens design from scratch or bringing a comprehensive lighting concept to life, our precision engineering and high-performance standards ensure that every lens we produce meets and exceeds expectations.

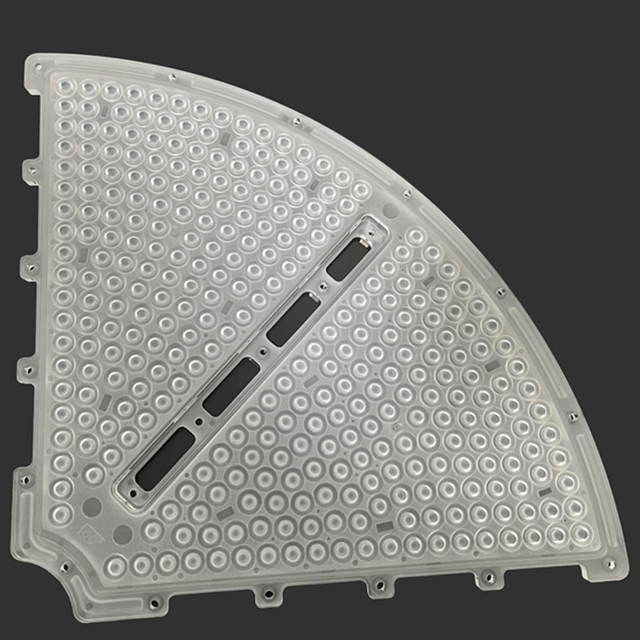

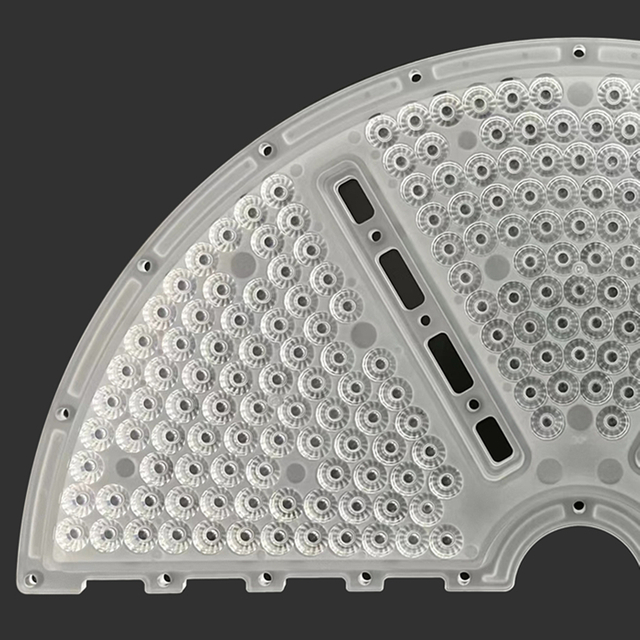

- High-Quality MaterialsWe use optical-grade materials such as PMMA (acrylic) and polycarbonate in the manufacture of our LED lenses. Renowned for their exceptional clarity and robust durability, these materials guarantee outstanding light transmission properties, making them ideal for a range of indoor and outdoor applications, including architectural lighting, retail lighting, and industrial LED lighting solutions.

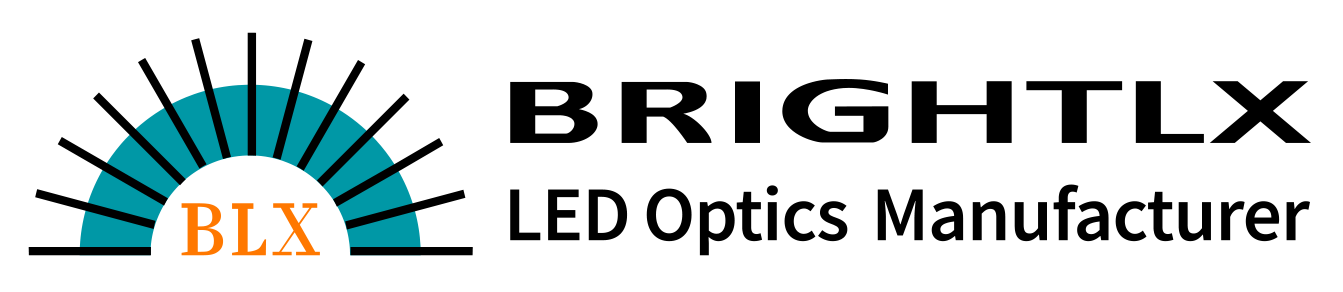

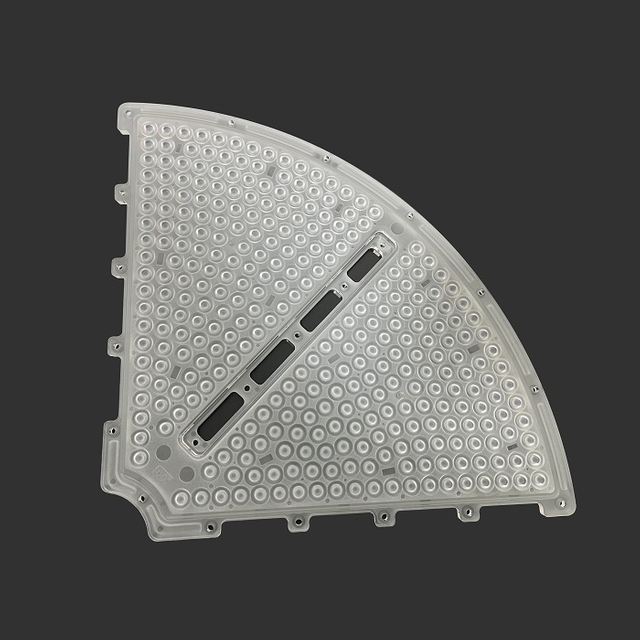

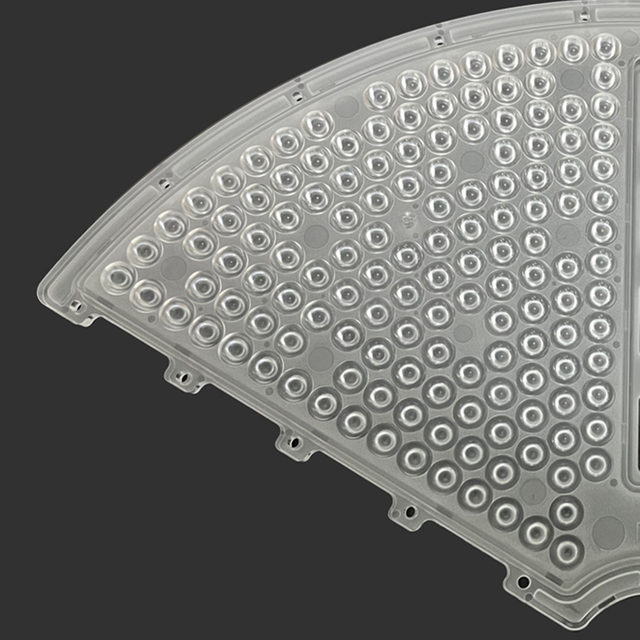

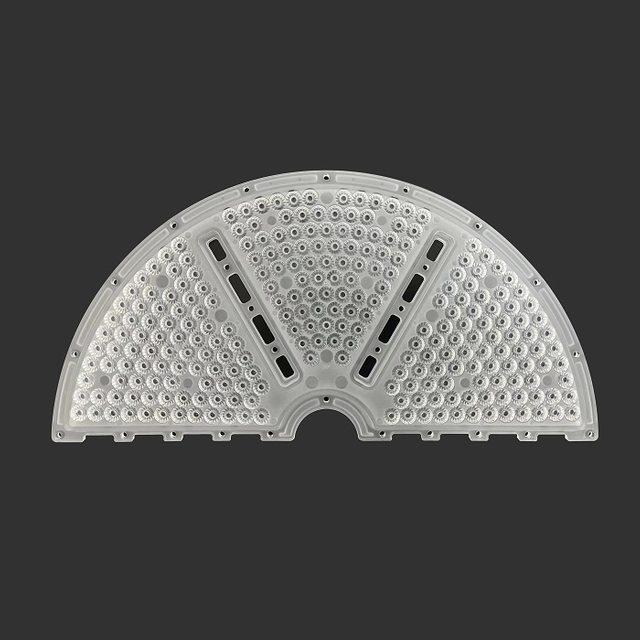

- Custom Design ServicesSpecializing in LED lens design and manufacturing, we excel in creating tailored LED lenses for specific beam angles, light diffusion patterns, and light distribution needs. From the initial conceptualization phase to the final production stage, we collaborate closely with our clients to develop bespoke lens solutions that precisely match their specifications and application requirements. This personalized approach not only enhances energy efficiency but also promotes sustainable lighting solutions tailored to each unique project.

- Complete Manufacturing ProcessOur in-house manufacturing capabilities cover the entire production cycle, from design and prototyping to mold making, injection molding, and extrusion. Leveraging advanced CNC machining and polishing techniques, we ensure that every lens adheres to stringent quality control measures. This all-inclusive process facilitates swift delivery timelines and highly competitive pricing, making us a reliable and efficient Led Lens custom manufacturer.

- R&D and InnovationOur dedicated research and development team is constantly engaged in pushing the boundaries of LED lens technology. By continuously exploring new designs and innovative lens technologies, we stay ahead of the curve in the LED market. We offer advanced light management solutions that boost brightness, control glare, and shape beams in custom lenses, providing clients with cutting-edge lighting options that meet their precise needs.These robust capabilities consolidate our position as a trusted and preferred Led Lens custom manufacturer for customers seeking high-precision, cost-effective, and dependable LED optics. Whether you require custom extruded linear lenses, asymmetric beam lenses, or specialized Total Internal Reflection (TIR) linear lenses, our team is fully committed to delivering the optimal solution for your project. Our extensive expertise, coupled with our unwavering dedication to quality and innovation, ensures that we remain a leader in the field of LED lens manufacturing.