- 1. Customization ExpertiseAs a Custom Led lens manufacturer, we specialize in custom LED lens solutions, offering tailored beam angles (e.g., 30°, 60°, 90°) and optical profiles to meet specific lighting requirements. This expertise enhances performance and visual appeal, ensuring that each project achieves its desired aesthetic and functional goals. From initial concept to final production, we work closely with clients to develop custom lens solutions tailored to their exact specifications and application needs. Our deep understanding of customization promotes energy efficiency and sustainable lighting solutions, making us a preferred partner for businesses seeking innovative LED optics.

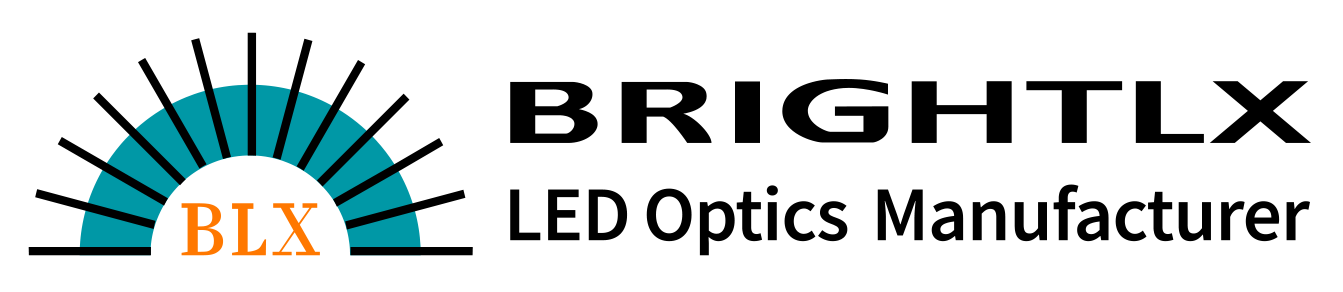

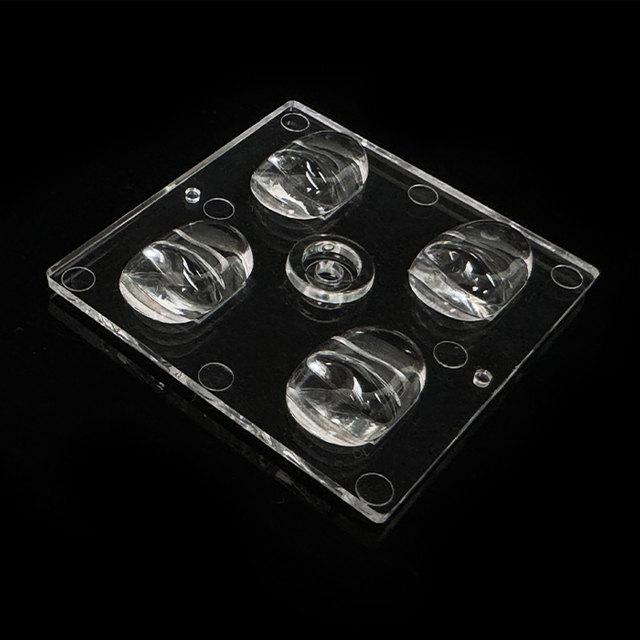

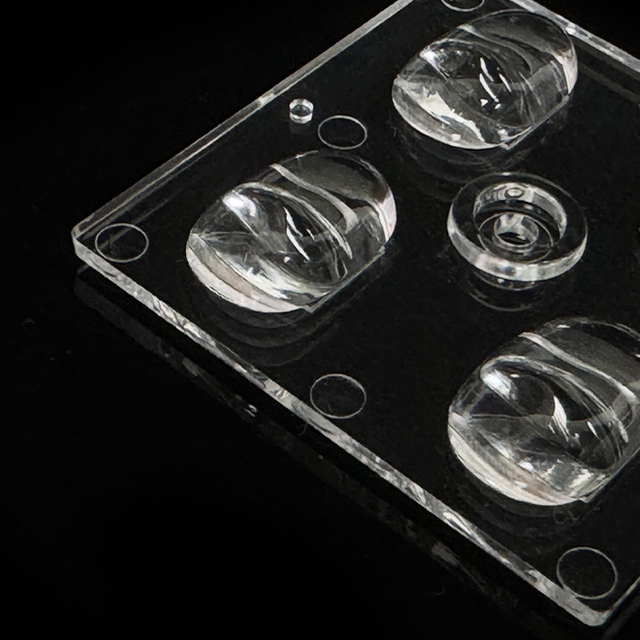

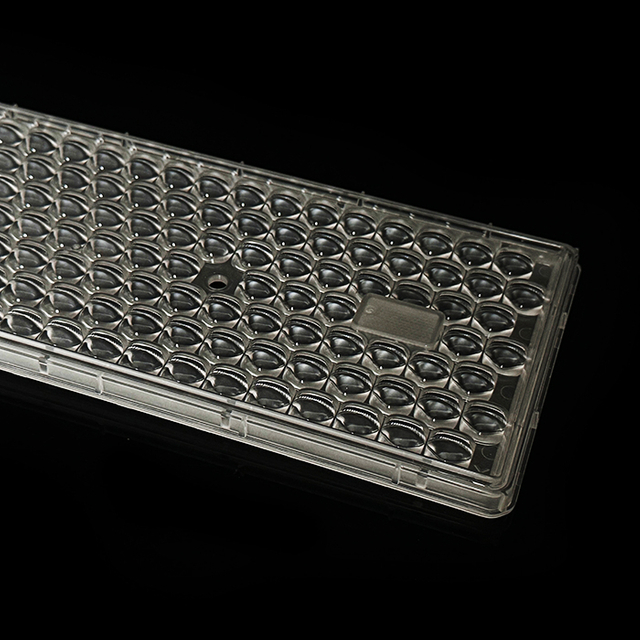

- 2. High-Quality MaterialsOur LED lenses utilize optical-grade materials such as PMMA (acrylic) and polycarbonate, renowned for their clarity and durability. These materials not only ensure exceptional light transmission but are also perfect for both indoor and outdoor applications, including architectural lighting, retail lighting, and industrial LED lighting. Our commitment to using top-tier materials guarantees reliability and performance, setting us apart as a trusted Custom Led lens manufacturer.

- 3. Complete Manufacturing ProcessWe handle every aspect of the manufacturing process in-house, from design and prototyping to mold making, injection molding, and extrusion. Leveraging advanced CNC machining and polishing techniques, we ensure that every lens meets stringent quality standards. This comprehensive approach not only enables fast delivery but also allows us to offer competitive pricing, making us a cost-effective Custom Led lens manufacturer.

- 4. R&D and InnovationOur team is deeply dedicated to continuous research and innovation, constantly developing new designs and lens technologies to stay ahead in the LED optics market. As a forward-thinking Custom Led lens manufacturer, we offer cutting-edge light management solutions that enhance brightness, control glare, and shape beams in custom lenses. Our innovative spirit ensures that we remain at the forefront of LED optics technology, delivering solutions that exceed customer expectations.These capabilities make us a trusted provider of custom LED lenses, linear light diffusers, and optical solutions for customers seeking high-precision, cost-effective, and reliable LED lenses. Whether you need custom extruded linear lenses, asymmetric beam lenses, or specialized TIR linear lenses, our team of experts is dedicated to delivering the right solution for your project. As a leading Custom Led lens manufacturer, we are committed to excellence in every aspect of our work, ensuring that your lighting needs are met with precision and innovation.