- Flexible MOQWe cater to both small-scale and large-scale projects, ensuring flexibility and cost-efficiency.

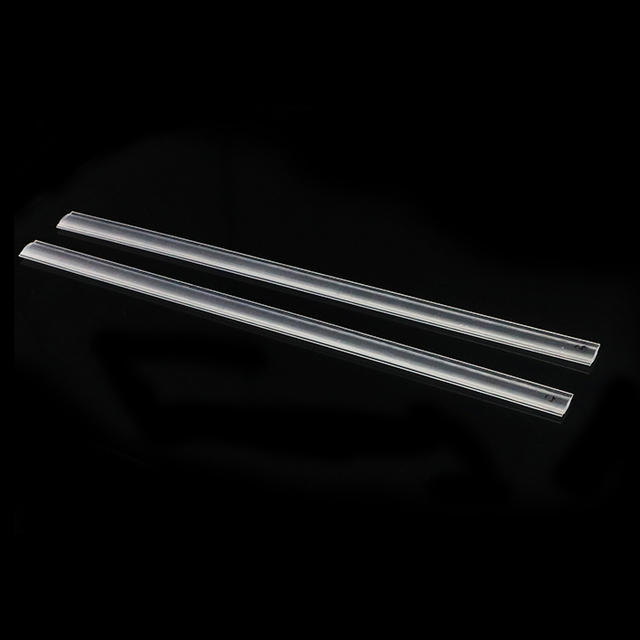

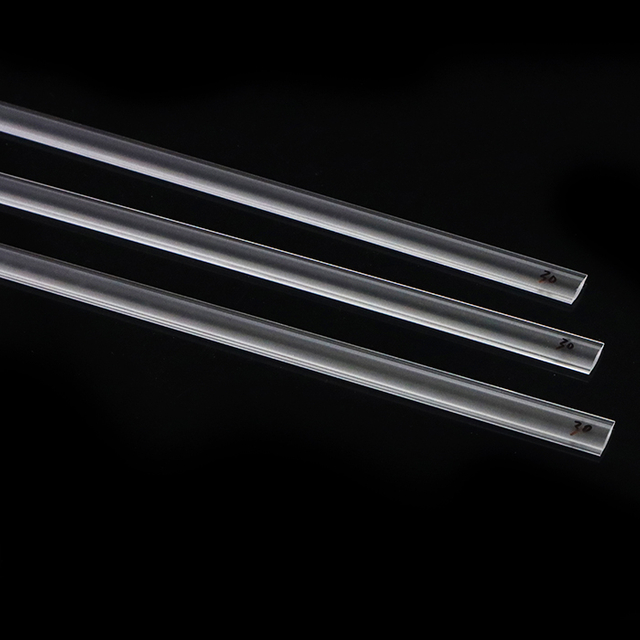

- High-Quality MaterialsWe use premium optical-grade materials like PC (Polycarbonate) and PMMA (Acrylic), which provide superior light transmission, UV resistance, and thermal stability for various lighting applications.

- Tailored SolutionsOur team can design custom extruded lens profiles, adjusting beam angles, light diffusion, and shape according to specific LED luminaire requirements. This includes solutions for linear lighting, strip lights, high bay lights, and more.

- Precision ManufacturingWith advanced extrusion equipment, we ensure that each extruded LED lens meets precise specifications, delivering consistent quality and optimal performance in commercial, industrial, and architectural lighting.

By focusing on customization, quality, and efficiency, we aim to be your trusted partner in delivering top-notch extruded linear lens solutions.