- OEM/ODM ServicesWe provide OEM and custom LED linear lenses to meet specific client needs. Whether it’s a unique lens design or bringing a full concept to life, we deliver precise engineering and high performance.

- Flexible MOQWe offer low minimum order quantities, allowing clients to start with small batches for testing and prototypes before scaling up. This is ideal for startups and specialized projects.

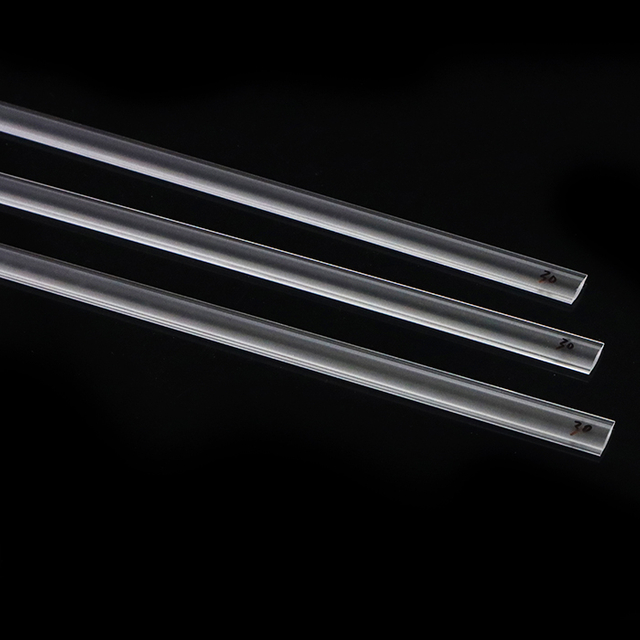

- High-Quality MaterialsOur LED lenses use optical-grade materials like PMMA (acrylic) and polycarbonate, known for their clarity and durability. These materials ensure great light transmission, perfect for both indoor and outdoor use, including architectural lighting, retail lighting and industrial LED lighting.

- Custom Design ServicesWe specialize in custom lens design, creating unique linear profiles tailored for specific beam angles, light diffusion, and distribution. Our solutions suit linear fixtures, LED strips, line lighting, recessed, and surface-mounted lighting.

- Complete Manufacturing ProcessWe handle everything in-house, from design and prototyping to mold making, injection molding, and extrusion. Using advanced CNC machining and polishing, we ensure every lens meets strict quality standards. This all-in-one approach enables fast delivery and competitive pricing.

- R&D and InnovationOur team is dedicated to continuous research and innovation, developing new designs and lens technologies to stay ahead in the LED market. We offer light management solutions to enhance brightness, control glare, and shape beams in custom lenses.These capabilities make us a trusted provider of custom LED lenses, linear light diffusers, LED strip lenses, and optical solutions for customers seeking high-precision, cost-effective, and reliable LED optics. Whether you need custom extruded linear lenses, asymmetric beam lenses, or specialized TIR linear lenses, our team is dedicated to delivering the right solution for your project.